Today marked the conclusion of week three of the project, and things are moving along steadily.

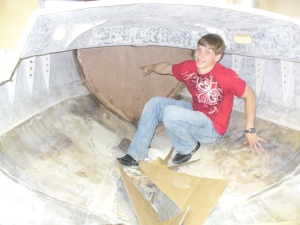

The class spent some time in the shop during the week sanding, cleaning the spars, and scrubbing deck hardware, while others continued to chip/gouge/pry/slice the remaining pour-in foam out of the aft area of the boat. We ultimately decided to remove a small bulkhead at the aft end of the cockpit to gain access to the foam from under the deck. Additionally, we opened up a 12″x12″ hole in the aft deck to improve access, which made a significant difference. Tony, Michael R., Nick and Alex S. chipped away at it, and Tony finally finished the job today, pulling out chunks of foam occupied by a colony of large black ants.

Nick removes foam from the aft compartment

Opening up the hole in the aft deck confirmed what we already knew: the majority of the balsa core that strengthens the deck structure is soggy and rotten. That means it’s necessary to remove most of the top layer of fiberglass on the aft deck, scoop away the old balsa, and then re-glass the entire area, carefully fairing it before painting. I know there are at least two other areas of substantial core damage that will need to be addressed as well.

Michael D., Joey W. and Oliver S. completed the first step in preparing the topsides for sanding by transferring the bottom of the boot stripe (the horizontal red line at/near the waterline) 3″ lower. Doing so allows us to sand the topsides and boot stripe while maintaining a reference line that we can bring back up 3″ when the time comes to paint the new boot stripe.

Michael D. transfers the bootstripe

Matthew O. tackled the rudder repair Wednesday afternoon. Earlier, we had removed two of the three boards that comprise the rudder blade, leaving the primary board that attaches to the rudder post in place. The two pieces we removed had separated (if they were ever attached) from their surrounding joints, and a previous owner had attempted unsuccessfully to re-attach them with some kind of caulk. We removed the caulk and cleaned up the edges with a light sanding. Matthew O. wiped the mating surfaces with acetone while I mixed up some epoxy. We coated the raw edges in unthickened epoxy, then added thickener to the mix and bonded the pieces of rudder blade to each other, making sure that plenty of epoxy oozed out from the joints. We smoothed the excess and left the epoxy to set.

Matthew O. preps the rudder sections for epoxy.

The first rudder section is epoxied to the main portion of the blade

Today I sanded down the epoxy that had squeezed out of the joints, and gave the rudder a light sanding to prepare the surface for fairing with thickened epoxy. We used up our last little bit of hardener, so we had only enough epoxy to fill two holes in the blade, which allow access to threaded rods that support the blade, and give the top portion a coat of fairing compound. We’ll finish fairing next week when we have more materials. In the meantime, the rudder is looking good and inspires much more confidence than it did a few days ago.

Rudder with a thin coat of fairing epoxy (before we ran out of epoxy)

Rudder blade epoxied together and sanded

Once again, I donned the full-face respirator and climbed into the cabin to finish sanding the sides and overhead. Sadly, I’ve discovered that it’s much more difficult to hold a 6″ RO sander over my head for any length of time than it used to be just a few short years ago! The good news is that this portion of the job is nearly over. There is only a small patch (that I forgot) that needs sanding. When that’s done, we are officially ready to begin reconstructing the cabin interior. I’ll be happy to be into reconstruction, which should begin next Friday.

Nick and Alex S. spent much of the afternoon polishing the various pieces of deck hardware and rigging – winches, cleats, chainplates – and had a very shiny (and pretty) collection before too long. As Tony remarked, the boat will look like new when she’s finished.

Freshly polished hardware

We concluded the day’s work with a good cleaning of the boat and the shop. And then we did the most enjoyable thing of all…we spent half an hour sitting in the empty cockpit admiring our work and imagining the future. These are great kids.